Swapping “you get what you pay for” for

“quality items at reasonable prices”

That was our motivation at NITORI

when

we overturned

widely-held perceptions

in the school bag industry.

In a sense, the traditional school bag industry in Japan has ignored cost-cutting measures on the basis that customers “will pay for quality.” Follow us on the journey we took to create a product that overturned this widely-held perception, by striking a balance between “reliable quality” and “affordable prices” at every stage of the process, from development to production, logistics and sales.

The ChallengeCreating a school bag of “reasonable quality at a low price”

The ChallengeCreating a school bag of “reasonable quality at a low price”

In Japan, school bags accompany children throughout their six years at elementary school. Therefore it’s only natural that parents and grandparents are keen to buy their children or grandchildren something of quality, no matter the cost. Does that mean we can just give up on trying to lower prices? Our answer at NITORI is, “Certainly not.”

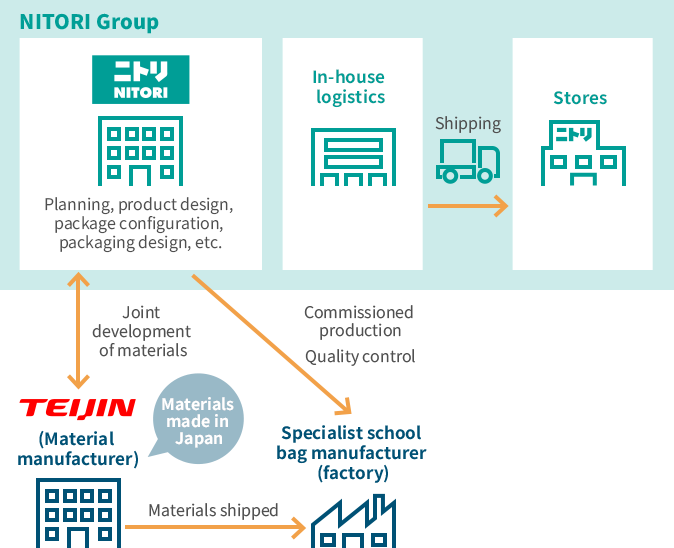

Our ability to strike a balance between “reliable quality” and “affordable prices” is down to the fact that we handle everything in-house, from product development to production, logistics and sales. Our approach to business of combining manufacturing and retail enables us to ensure quality through reliable manufacturing, whilst at the same time cutting costs and intermediate margins wherever possible so that we can maintain low prices. When we took on this new challenge, we believed that by playing to our strengths, we should be able to create a school bag that would offer “reasonable quality at a low price”.

Laying the foundationsCreating a framework to provide quality products at reasonable prices

Laying the foundationsCreating a framework to provide quality products at reasonable prices

What is a reasonable level of quality for a school bag? At what price would we be able to maintain that quality? We started our quest to produce a NITORI school bag by working out answers to these questions. Through a process of trial and error, including sourcing bags from domestic manufacturers and getting bags manufactured at affiliated factories in other countries, we built up a degree of expertise in manufacturing and selling school bags. In particular, we focused on “durability”, ensuring that the materials and structure of each bag could stand up to being used through six years of elementary school.

We worked on materials with Teijin, a world-renowned company in the field of artificial leather for use in sports. Together, we developed ToughGuard® Light, an artificial leather that is both light and strong. We achieved the structure we wanted through careful stitching. We came up with a range of other innovations too, until several years later we set out rigorous production standards for overseas factories, and established a framework capable of supplying reasonably priced yet high quality school bags that would be guaranteed to last for six years.

Another reason we were able to guarantee reliable quality was by working with an established domestic bag manufacturer. We commissioned them to manufacture our products, and guaranteed that we would buy the entire production run, which enabled us to conclude a contract at a lower price. Drawing on expertise from the manufacturer’s craftsmen and women, we also set out clear operating procedures and quality check points, which dramatically improved the quality of NITORI school bags.

Designing sales areasSharing our passion with individual customers through our sales areas

Designing sales areasSharing our passion with individual customers through our sales areas

Having created our “Wanpaku-gumi” series, we have now grown into one of the frontrunners in the mass-market school bag sector. However, our products didn’t necessarily start off with a great reputation. One of the reasons for that was a lack of understanding amongst sales staff interacting with customers. When a customer would ask, “how is that product so cheap?”, a sales assistant would answer, “because it’s made overseas”. That was enough to put people off buying our bags. We therefore organized a workshop before the start of the sales season, to find a way to communicate to customers visiting sales areas of the effort and commitment we put into quality and price. As a result, we made improvements in putting passion into our sales areas and as a result, the conversation with customers became lively. That made customers appreciate both the appeal of NITORI school bags and our underlying commitment, and paved the way for the vibrant sales areas we have today.